The combined reverse osmosis (RO) and electro-deionisation process produces ultrapure water.

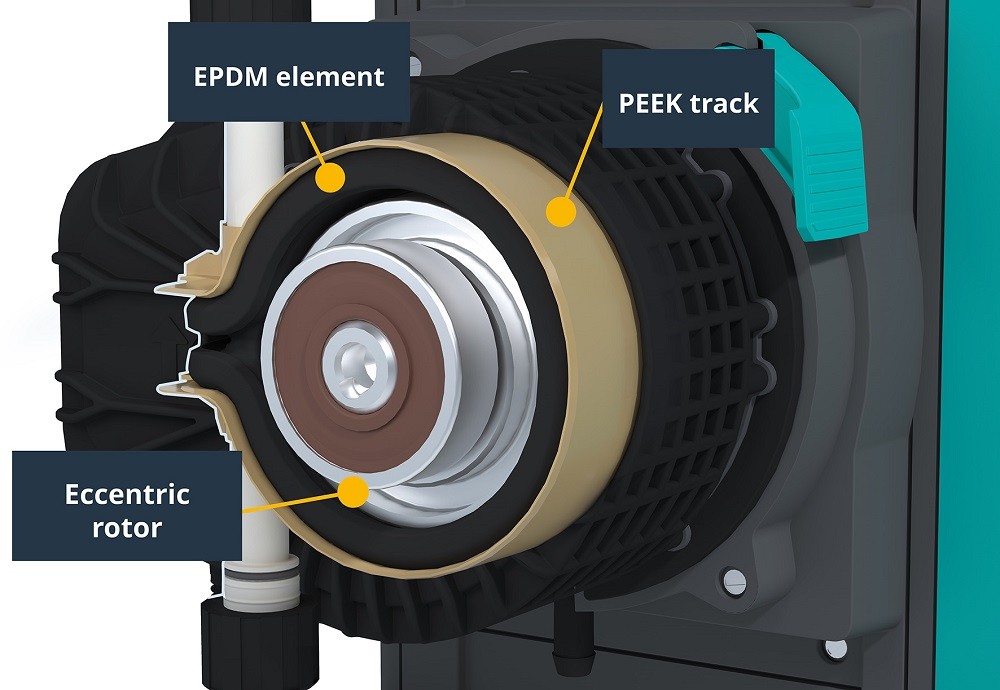

WD News: The long-life of Qdos Conveying Wave Technology (CWT) chemical metering pump is benefitting an industrial water purification facility operated by Veolia WTS in Italy as Andrea Rossi, sales engineer at WMFTS, explains.

The pump is dosing inlet river water with sodium hypochlorite (NaCIO) as part of a process to produce ultrapure water to tight resistivity requirements. The plant produces ultrapure water for steam generation, which feeds into a turbine producing energy for a chemical production facility. It is situated in the city of Ferrara in northern Italy and water is sourced directly from the River Po.

Veolia WTS runs the plant on a build-own-operate contract, where the end-user pays only for the treated water. The comprehensive treatment process at the plant is underscored by careful water quality monitoring to deliver water that meets the specific requirements of the end client.

Veolia WTS’s plant maintenance manager, Davide Spinola, said, “We are producing ultrapure water with a resistivity of 17 ohm-metres per centimetre (Ω⋅m/cm). The process begins by treating water coming from the River Po and involves dosing controlled quantities of NaCIO to optimise the functionality of the reverse osmosis plant.

“We dose sodium hypochlorite upstream for water disinfection, then perform double-pass reverse osmosis, followed by electro-deionisation,” said Spinola. “Reverse osmosis involves a semi-permeable membrane that removes unwanted contaminants and molecules, while electro-deionisation is a continuous, chemical-free process that removes ionised and ionisable species from feedwater using DC power.”

Several Qdos pumps are already installed at the Ferrara site, dosing in different applications. It was this experience of the efficiency of Qdos that led to the decision to work closely with engineers from WMFTS to trial the ground-breaking Conveying Wave Technology (CWT) model.

According to Spinola, they have several pumps on site, including a Qdos model with ReNu PU pumphead for polymer dosing. When they heard about the operating principle of the Qdos CWT, they were keen to try it in place of our existing diaphragm pump.

Ongoing Trial

Installation of the Qdos CWT at the Veolia WTS plant took place in November 2020 and it has continued to perform beyond the initial trial. The pump doses sodium hypochlorite with the range of 4-20mA input signal at a flow rate of 3 litres/hour (l/h) in winter, rising to approximately 15l/h in summer.

Absolute consistency is required in the production of ultrapure water, which is used in numerous industries.

“Many industries require ultrapure water for their processes, but this was a particularly demanding application, which is one of the reasons we were keen to trial Qdos CWT at the Ferrara site. Consistency is key to producing ultrapure water, but here there was the additional challenge of the seasonable variability of the river water entering the plant, with changing quantities of soluble and non-soluble contaminants,” said Andrea Rossi, sales engineer at WMFTS.

Commenting on the Qdos CWT installation, Spinola said, “We’ve not had a single issue since day one. Nothing has been replaced and no service needed; it has been a fit and forget solution.”

Source & image courtesy: Watson Marlow Fluid Technology Solutions