By Dr Sabarna Roy, DI Business Head – Sales & Marketing, The Sandur Group

Ductile iron pipe, made from ductile cast iron, is a graphite-rich cast iron in which the graphite has a spheroidal shaped molecular structure. This molecular structure makes the cast iron less brittle and more resistant to impact than the other varieties, which have a flaky structure.

The ductile iron pipe is used in trenchless technology for water and sewer lines. Ductile iron pipes can have a life of more than 100 years if they are coated within and without with non-corrosive linings like cement, asphalt, paint, or polyethylene encasement.

Since this material can withstand the toughest conditions, ductile iron pipes are ideal for hilly terrains.

KEY POINTS

1. Three kinds of pipelines can be considered as options:

- Socket and spigot ductile iron pipes.

- Double-chambered restrained joint ductile iron pipes.

- Double flanged ductile iron pipes.

2. Socket and spigot ductile iron pipes and double flanged ductile iron pipes can be considered in over ground installation whereas double chambered restrained joint ductile iron pipes can be considered in underground installation.

3. Surge analysis and subsequent protection should be made mandatory.

4. Proper and adequate valve placement of line isolation valves, air release valves and scour valves should be made mandatory.

5. There are three kinds of slopes considered:

- >0° up to 10°

- >10° up to 25°

- >25°

CASE 1: SLOPE BETWEEN > 0° AND 10°

A. For RJT Pipes and Fittings at Bends Socket and Spigot Pipes in the Balance Portion in Underground Installation:

- Crown depth from existing ground level should be considered as 1000 mm, and below the pipe, there should be a provision for 100 mm for sand bedding.

- After the pipes and fittings have been assembled, the entire trench shall be backfilled with imported dry fine granular soil.

B. For Socket and Spigot and Double Flanged Pipes in Over Ground Installation:

- For socket and spigot pipeline in over ground application, we should construct a saddle support for each pipe behind the neck of the socket, and an encasing anchor joint for every third pipe in the middle.

- For bend portion, a thrust block shall be constructed in RCC construction, and the bottom of the foundation shall be taken up to 1 metre from the existing ground level.

- Double flanged pipes shall be 4 metre in length, and saddle support shall be provided in every second pipe, and the unsupported length shall be 8 metres.

CASE 2: SLOPE BETWEEN > 10° AND 25°

A. For RJT pipes and fittings at bends socket and spigot pipes in the balance portion in underground installation:

- Same as for slope between 0° and 10°.

- For the socket and spigot ended portion of the pipeline, every third pipe in underground installation shall be encased in a concrete block.

B. For Socket and Spigot and Double Flanged Pipes in Over Ground Installation:

- In over ground pipeline for socket and spigot pipes, encasing anchor joint shall be constructed for every pipe behind the neck of the socket.

- For bend portion, a thrust block shall be constructed in RCC construction, and the bottom of the foundation shall be taken up to 1 metre from the existing ground level.

- Double flanged pipes shall be 4 metre in length, and saddle support shall be provided in every pipe, and the unsupported length shall be 4 metres.

CASE 3: SLOPE > 25°

In this case, underground pipeline should be considered in a combination of double chambered restrained jointed pipes and fittings, and balance portion in socket and spigot pipes where each and every socket and spigot pipe shall be encased in a concrete block.

POINTS TO BE TAKEN CARE OF WHILE DESIGNING THE PROJECT

- Surge analysis and precautions for arresting unbalanced surge as per the design criteria.

- Right positioning of the air valves.

- Proper selection of bends/restrained joints in changes in slope/alignment.

- Right positioning of non-return valves.

- Maintaining proper soil cover in the pipeline trench. Proper backfilling and compaction to be done.

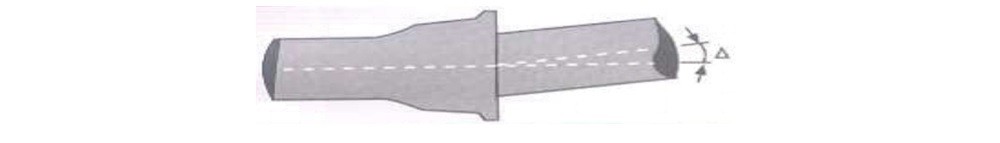

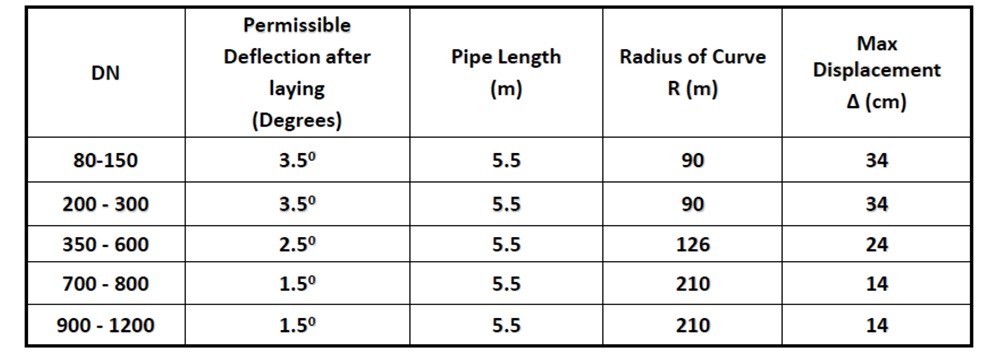

MAXIMUM DEFLECTION ALLOWED IN A FLEXIBLE S/S PIPELINE

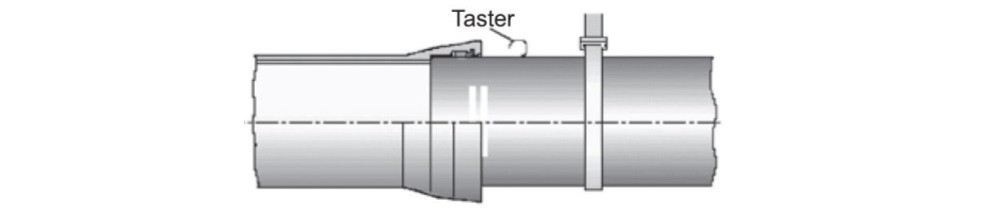

CHECKING OF A PIPELINE AFTER JOINTING

After jointing, the end of the socket must lie between these two bands. Spigot should be inserted in socket, and not vice versa. If accidentally socket is pushed – then the gasket may be displaced and concentricity of the spigot and socket may not be achieved.

It is always recommended that a quick visual check be performed after assembly and deflection are complete. Using a flashlight, look down the barrel of the pipe to inspect the joint.

Feeler Gauge Test: Check the barrel of the pipe with a feeler gauge to be certain. The feeler gauge (small rod, a thin piece of metal, or even a paper clip) will help verify if the gasket is seated where it should be. You do this by inserting the feeler gauge between the small gap that exists between the bell face and the spigot. Continue to feel around the joint with the gauge. The gauge will identify voids or if the gasket has slipped out of socket.

PRECAUTIONS TO BE TAKEN IN A RUBBER GASKET

A. Storage of Gasket

Often pipes are laid much later, after the pipes and gaskets are procured. Before use, check if the gasket is compatible to the socket design. For storing gaskets, certain precautions need to be taken because of their characteristics. The important parameters are:

- Storage Temperature: The storage temperature must be below 25°C In extreme cold weather. Before use, their temperature must be brought to about 20°C by immersion in tepid water. Gaskets must not be stretched or deformed at low temperature.

- Humidity or Dryness of the Storage Atmosphere: Vulcanised elastomeric joint gaskets must be stored under clean and moderately humid conditions.

- Exposure to Light and Oxidation: Elastomers are sensitive to ultraviolet light and ozone. Stored gaskets must therefore be screened from light (direct sunlight and artificial light).

- Duration of Storage: Push on joint gaskets and flat gaskets stored under the above conditions can be safely used within a period of six years from the date of manufacture.

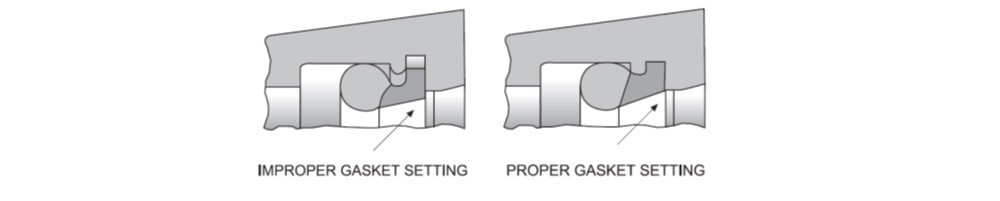

B. Fitting the Gasket in a Socket Profile

- Clean the gasket groove thoroughly for proper seating of the gasket.

- A layer of lubrication is to be applied on the exposed surface of the gasket, on the chamfer and the spigot end up to the mark. The lubricating paste is brush applied. Detergent and petroleum base lubricant should not be used. Soft soap or vegetable oil may be used.

- Before inserting inside socket, bend the gasket in a heart shape as shown and press the extended portion of the gasket in to the groove.

C. The Fitment in a Socket Profile

- Place the gasket properly into the groove. Check that the heel is locked in the locking grove as shown in the figure below. After putting the gasket, it should be wiped clean and inspected for damage. Apply some lubricant on the gasket also.

ABOUT THE AUTHOR

Dr Sabarna Roy is DI Business Head – Sales & Marketing at the Sandur Group.

Sandur Manganese & Iron Ores Limited (SMIORE) is in the market with mining, ferroalloys, coke, and energy and now SMIORE is diversifying into ductile iron pipes and pig iron. SMIORE is coming up with an 0.3 MTPA ductile iron pipe plant and 0.1 MTPA pig iron plant at Hospet as a part of SMIORE’s forward integration process by the first half of the next year.

Nice. Keep on writing. will help people want to know more about pipe line.