By Dr. Sabarna Roy, DI Business Head – Sales & Marketing, The Sandur Group

The advantages and disadvantages of manufacturing ductile iron pipes as per ISO 2531 for water application and ISO 7186 for sewerage application, and whether harmonisation of Indian Standards is required in line with International Standards needs to be deliberated widely in the industry and amongst stakeholders.

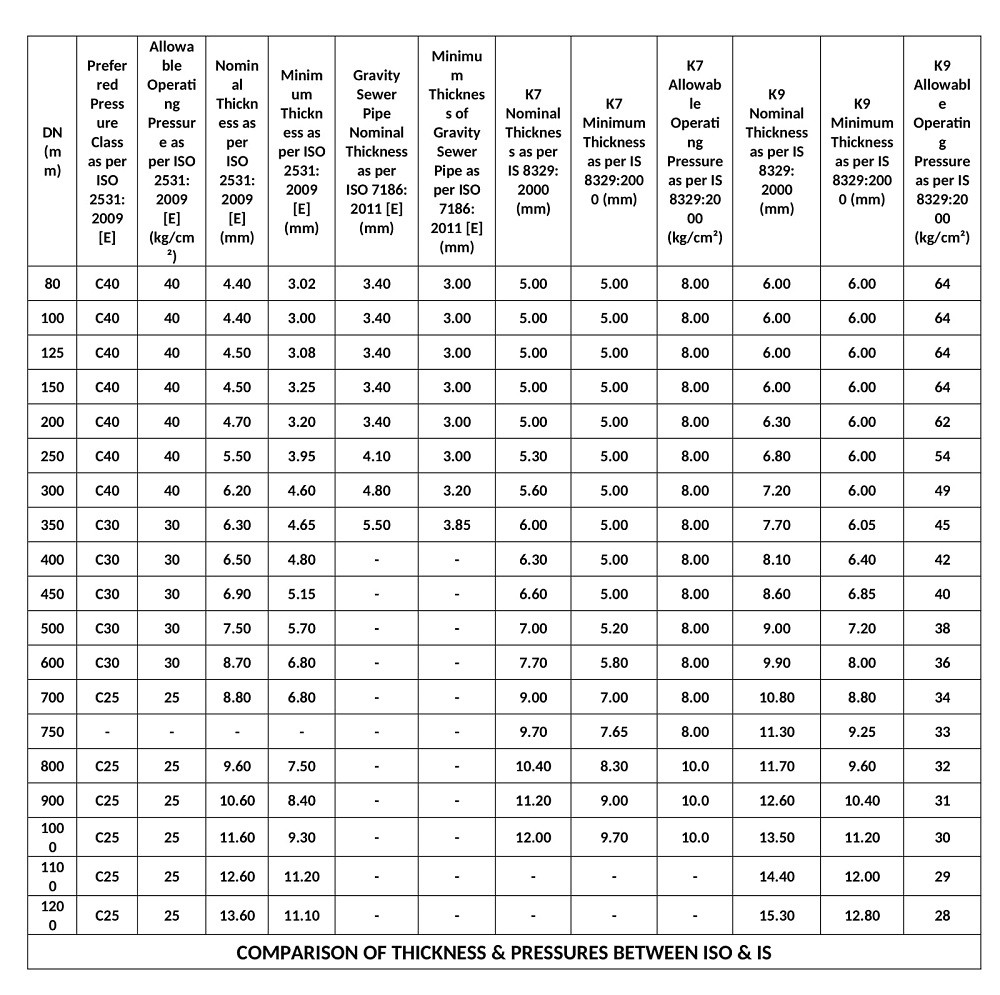

A thickness and pressure comparison between ISO and IS for ductile iron pipes is given in Table 1, for ready reference.

IS 8329:2000 is based on ISO:1998 [E], which is based on thickness Class K series. While ISO 2531 has migrated to pressure Class C series in its 2009 version, there has been no change to this effect in IS 8329 because it has not been revised in the last 22 years.

ISO 2531:1998 [E] specified the thicknesses of Class K9 pipes and pressure rating of Class K9 pipes only. But IS 8329:2000 contains thicknesses and pressure rating of K7 pipes also. The thicknesses of K7 pipes were evaluated based on the formula given in the Clause 4.3, which is also appearing in ISO 2531:1998 [E]. However, the pressure rating of K7 pipes in IS 8329:2000 has been incorporated without any rationale or logic.

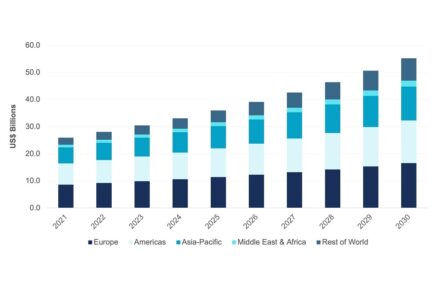

A closer look at the above table will reveal that the modern version of ISO allows higher pressures with lower thicknesses, metallurgical properties remaining constant. By adopting ISO 2531 in India, a huge impact will be created on the cost of schemes, allowing flexibility to engineers to adopt products suitable to their schemes, enabling procuring agencies purchase pipes and fittings from a wide range of available options, causing reduction in transporting and installation costs as well as reducing colossal wastage of resources as sunk cost of schemes.

The savings in resources shall not only reduce the cost of implementation of water supply projects but will also reduce the impact on environmental cost. Adopting International Standards will also improve the manufacturing capability of manufacturers and enable them to cope in the increasing competitive pipe market in India and abroad.

Certain state government procurement policies in water supply obstruct BIS license holders who are new manufacturers in India by incorporation of various restrictive clauses in the tender document.

It must be understood that BIS licensing process is in line with its transparently published product manual for centrifugally cast ductile iron pressure pipes for water, gas and sewage according to IS 8329:2000.

This product manual refers to quality processes to be followed in case of raw materials. Grouping guidelines are given; list of testing equipment required at the plant are given which is required to be followed; scheme of inspection and testing is detailed out including levels of control, and proforma of test certificate.

This product manual is very rigorous and the obtaining process of BIS licensing thereby ensures the quality accreditation of the manufacturers. Imposing further restrictive clauses will result in the following implications:

• Government procurement for pipelines will be deprived of efficient price discovery mechanism and thereby reducing the potential of competitive project cost.

• Imposition of restrictive clauses will adversely affect new entrepreneurs in pipe manufacturing unit.

• The cost of capital resources will be wasted, and potential job creation efforts will go in vain.

• The latest technology in manufacturing with best equipment can remain unutilised thereby delaying technology adoption in the manufacturing sector.

Another aspect has been the incorporation of life cycle cost analysis approach in the selection of pipe materials for water supply.

Although this approach is incorporated in the Central Water Commission Pressurised Irrigation Network Manual of July 2017, to date, no irrigation project is designed considering the life cycle cost analysis approach. The New Age Pipe Committee Report circulated by the Department of Drinking Water and Sanitation, Ministry of Jal Shakti has also adopted life cycle cost analysis approach and yet no Jal Jeevan Mission Rural Project employs this approach to their schemes.

One must agree that most of our public and social infrastructure is constructed partly with borrowed money in a mixture of loans, soft loans and aids. In such a situation, public utilities cannot be expected to base their procurement policy on life cycle cost analysis.

While the numerical model for life cycle cost analysis is detailed in the CWC Manual and another approach is also detailed in ISO 21053 and there are many other approaches available, yet one must accept that the contentious issue is the comparative life cycle of various pipe materials used in water supply. For this, international documentation must be referred to but simulation tests are required to be carried out in Industry Grade Laboratories by testing pipes under Indian conditions.

These are some of the issues of concern that require further discussions and deliberation by concerned technical experts.

Sandur Manganese & Iron Ores Limited (SMIORE) is in the market with mining, ferroalloys, coke, and energy. Now, it is diversifying into ductile iron pipes and pig iron. SMIORE will come up with an 0.3 MTPA ductile iron pipe plant and 0.1 MTPA pig iron plant at Hospet as a part of its forward integration process by the first half of the next year.