By Dr Sabarna Roy, DI Business Head – Sales & Marketing, The Sandur Group

INTRODUCTION

The ability to manage an irrigation system is dependent on having an accurate estimate of the percentage of pumped water that becomes available for crop use. No irrigation system delivers water at 100 percent efficiency. Water may be lost through delivery systems or pipelines and some water may remain in the soil, but not be used by the crop. Some water may run off the soil surface into lowland areas. Still other water may be lost to evaporation in the air, or from the soil and plant surfaces. To know how much water to pump, these losses must be totalled and added to the amount of water needed by the crop.

Water application efficiency accounts for how uniformly the water is applied and can be used for other assessments. If a farmer is trying to decide whether switching to a new sprinkler package would be economical, the change in water application efficiency could be a major factor. If the water becomes limited, changing to a system with a higher water application efficiency will provide more usable water to the crop and reduce pumping costs.

BENEFITS OF USING IRRIGATION EFFICIENCY FOR DESIGNING A PROJECT

Environmental Benefits

It reduces the amount of water extracted for irrigation purposes, and the amount of water lost (in surface runoff in the fields and evapotranspiration). Energy requirements for pumping and conveying are subsequently reduced, minimising the carbon footprint. It minimises nutrient leaching and pollution of local watersheds due to decreased agricultural runoff.

Socio-economic Benefits

It reduces costs related to extraction and transport for irrigation. It contributes to food security and income generation (cash crops) due to high crop productivity and increases water availability for other uses, especially during dry periods.

OPPORTUNITIES AND BARRIERS

Opportunities

It can improve agricultural production in dry areas with limited access to freshwater resources. There are extended environmental and economic benefits, including cost savings and reduced risks of water source degradation. It leads to climate change adaptation and mitigation benefits, including increased community resilience to changing water availability. An understanding of the importance of water conservation in farming is likely to increase the chances of improving water efficiency in other sectors.

Barriers

Change in irrigation practices may change soil-water balance and reduce groundwater recharge. Agricultural water costs are heavily subsidised in many countries, providing little incentive to change from conventional (high water consuming) farming methods.

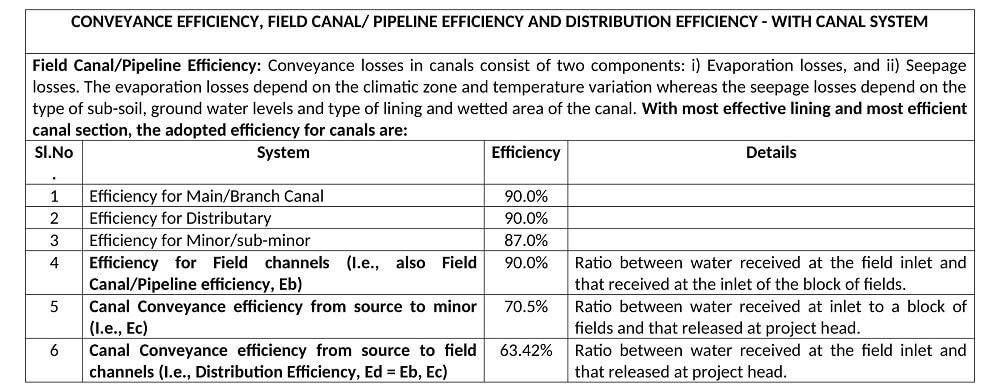

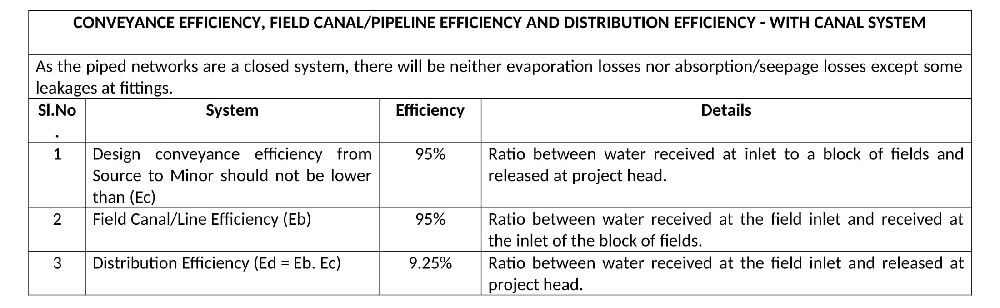

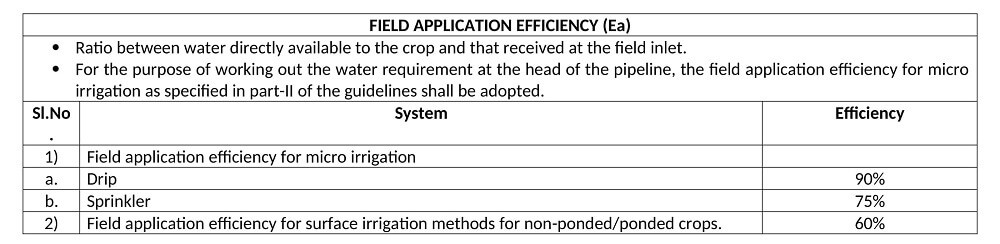

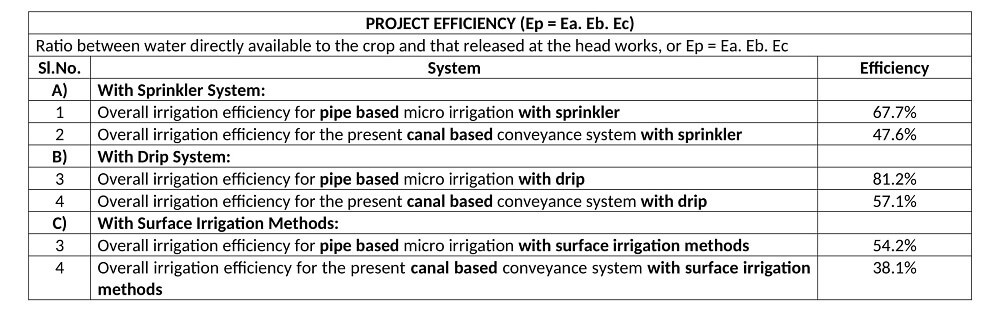

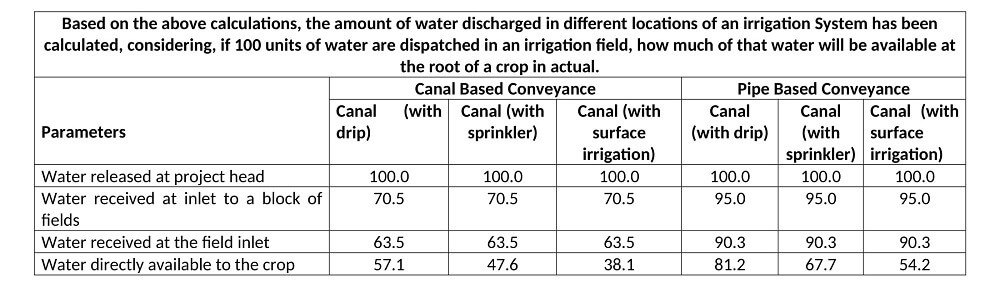

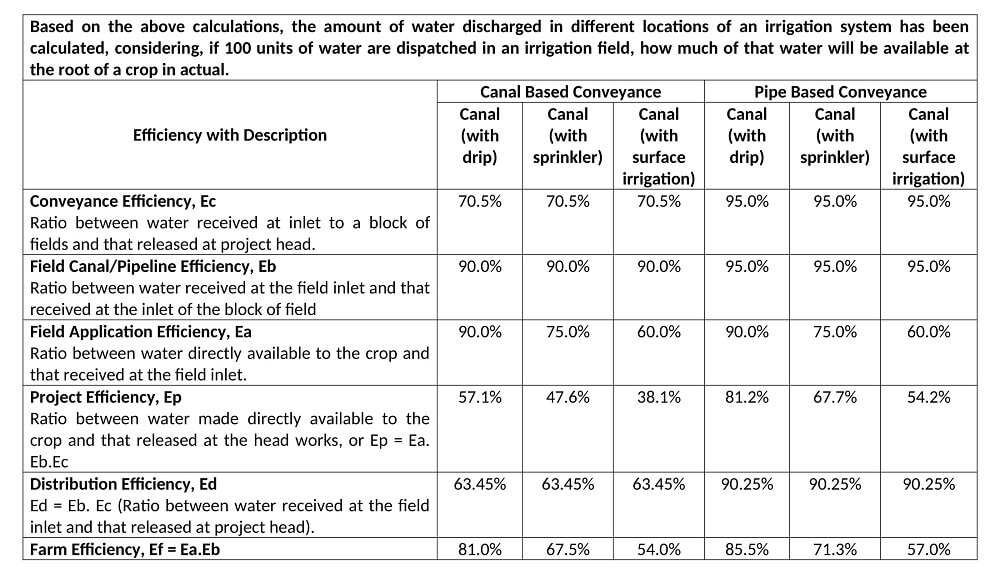

DEFINITIONS

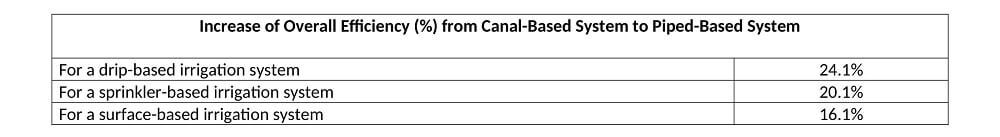

RESULTS

CONCLUSION

DUCTILE IRON PIPE: ISO 21053

As per ISO 21053: 2019 – Life cycle analysis and recycling of ductile iron pipes for water applications:

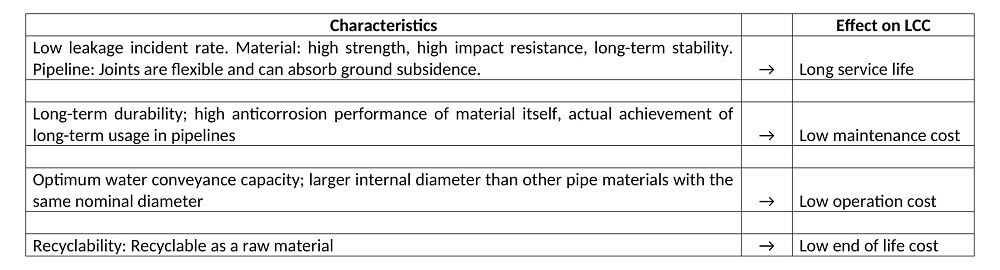

The following key drivers can be highlighted:

Leakage

Strong material properties and flexibility of joints contribute to prevent the leakage incident on buried ductile iron pipes. Annex C of ISO 21053: 2019 proposes examples of statistical values of incident rate per kilometre.

Durability

A service life of 100 years is commonly recognised for ductile iron pipes buried in usual conditions. However, the service life can be reduced or increased considering the nature of the pipe coating and the local soil conditions.

Conveyance Capacity

For a given nominal diameter, ductile iron pipes are duly designed with a larger internal diameter in order to reduce the head loss on energy pumping and the operation cost such as the electric power usage cost. Annex A of ISO 21053: 2019 shows that the internal diameter is a more influent factor on the head loss than the surface roughness coefficient.

Recyclability

Excavated iron pipes can be reused as a raw material to manufacture new ductile iron pipes. Benefits of lower-cost production can be expected in a case where natural resources are use, allowing the disposal cost to be reduced.

The development of new methods of laying (re-use of excavated soils for backfilling, narrow trench, etc) can also contribute to reducing the construction cost.

As per ISO 21053: 2019 – Life cycle analysis and recycling of ductile iron pipes for water applications are:

The methodology of Life Cycle Analysis has also been detailed in ISO 21053.

Sandur Manganese & Iron Ores Limited (SMIORE) is in the market with mining, ferroalloys, coke, and energy and now SMIORE is diversifying into ductile iron pipes and pig iron. SMIORE is coming up with an 0.3 MTPA ductile iron pipe plant and 0.1 MTPA pig iron plant at Hospet as a part of SMIORE’s forward integration process by the first half of the next year.

References:

1. Central Water Commission Pressurised Irrigation Network Manual, July 2017

2. ISO 21053.